GN Pan stands for Gastronorm Pan, a standardized food container system developed in Europe (EN 631 standard) and now used globally in commercial foodservice.

Originally introduced in Switzerland in the 1960s, GN pans are defined by modular dimensions, allowing them to fit universally into steam tables, chafing dishes, refrigeration units, ovens, and transport boxes.

Benefits of GN Standardization:

– Interchangeability: Compatible across various kitchen equipment and brands.

– Operational Efficiency: Streamlines prep, cooking, storage, and display.

– Modular Design: Multiple pans fit together in a full-size footprint.

Standard Sizes and Depths Explained

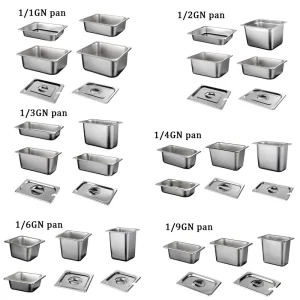

GN pans are based on a modular unit: GN 1/1, which measures 530 x 325 mm. All other GN pan sizes are fractions of this base unit.

| GN Pan Size | Dimensions (L x W in mm) | Description |

| GN 1/1 | 530 x 325 | Full size |

| GN 2/3 | 354 x 325 | Two-thirds |

| GN 1/2 | 325 x 265 | Half |

| GN 1/3 | 325 x 176 | One-third |

| GN 1/4 | 265 x 162 | One-quarter |

| GN 1/6 | 176 x 162 | One-sixth |

| GN 1/9 | 108 x 176 | One-ninth |

Common Depths:

| Depth (mm) | Typical Use |

| 20 | Shallow presentation (sushi, fruits) |

| 40 | Cold items, prep, portion control |

| 65 | Steam cooking, hot food holding |

| 100 | Baking, storage, large portions |

| 150 | Deep storage, soups, stews |

| 200 | Bulk cooking, catering |

Note: GN pans can also come with perforated bottoms for steaming or draining applications.

Material Comparison: 201 vs 304 Stainless Steel

Choosing the right material is essential for durability and food safety. The two most common stainless steel types for GN pans are 201 and 304.

| Material | Corrosion Resistance | Cost | Lifespan | Suitable Uses |

| 201 Stainless Steel | Moderate | Lower | 1–2 years | Dry storage, cold holding |

| 304 Stainless Steel | Excellent | Higher | 5–10 years | Steaming, acidic foods, high-use environments |

Typical Use Scenarios and Equipment Compatibility

Common Use Cases:

– Buffets – Easy swapping and portioning of hot/cold items.

– Catering – Transporting food while keeping the temperature.

– Bakeries – Dough proofing, batter holding.

– Refrigerated Prep Stations – Organizing ingredients efficiently.

– Steam Ovens – Cooking directly in the pan.

Compatible Equipment:

– Steam tables and chafing dishes

– Bain-maries

– Blast chillers

– Commercial ovens (with GN rails)

– Cold salad bars and prep counters

How to Choose the Right GN Pan (Buying Guide + Cost Analysis)

| Selection Criteria | Recommendation |

| Application | Steaming = 304 stainless; Cold storage = 201 sufficient |

| Pan Size | Match to your equipment cutouts |

| Depth | Prep = 65mm; Holding = 100mm+; Display = 20–40mm |

| Material | Choose 304 for longer service life and food safety |

| Perforated or Solid | Perforated for steaming; solid for general use |

Cost vs Value

| Material Type | Price Range (USD) | Lifespan |

| 201 Stainless Steel | $3–6 | 1–2 years |

| 304 Stainless Steel | $7–15 | 5–10 years |

| Polycarbonate Pan | $4–8 | 1–3 years (cold use only) |

Cleaning and Maintenance Tips

To extend the life of your GN pans:

– Always rinse immediately after using acidic foods.

– Hand wash or use low-temperature dishwasher cycles.

– Avoid abrasive pads that scratch the surface.

– Dry thoroughly before stacking.

– Inspect regularly for dents or rust.

About Yongyu – Trusted GN Pan Manufacturer

Yongyu is a professional stainless steel kitchenware manufacturer with over 15 years of experience, specializing in high-quality GN pans for commercial foodservice operations.

Why Choose Yongyu?

– ISO-certified production

– Full range of GN sizes & depths

– Both 201 and 304 stainless options

– Custom OEM/ODM support

– Fast delivery & reliable after-sales service

GN pans are not just simple containers—they are modular building blocks of modern commercial kitchens. With this complete Food Pan Sizes Chart, you now have the knowledge to choose the right size, material, and depth for your specific needs.

For dependable quality and long-term value, consider working with a trusted supplier like Yongyu.